Kistler

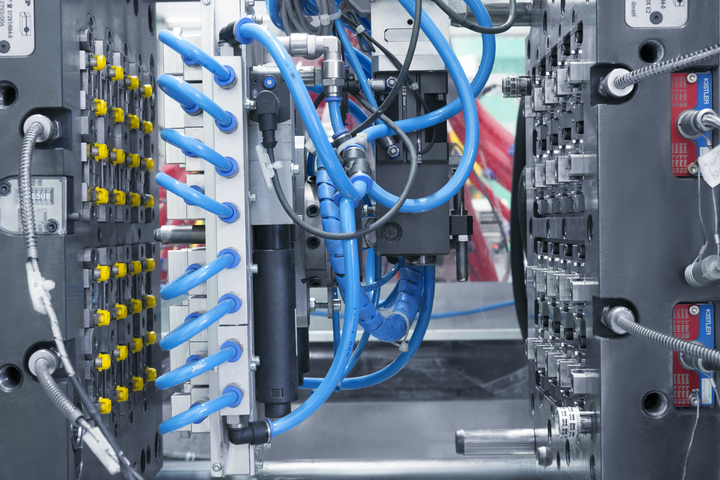

Combined with Kistler's ComoNeo process monitoring system, you can reduce scrap during plastic injection molding and achieve utmost transparency and process reliability. ComoNeo records all conditions in the mold during the injection molding process, enabling analysis, optimization, monitoring, and documentation of the injection molding process.

With ComoNeoPREDICT, an online quality prediction system involving artificial intelligence (AI), you can obtain reliable data about each manufactured component in advance based on the current cavity pressure profile. This allows you to improve machine settings and maximize quality, production time, and process stability.

ComoNeoMERGE provides a solution for precise and transparent control of complex multi-component injection molding processes, reducing quality costs by providing a clear evaluation of the entire process.

With ComoNeoLDAP and LOG, which are adapted for medical requirements, you can connect to the corporate user management and record a full audit trail. Data export via CSV is standard, as well as the OPC-UA export of all process values and evaluation results.

Contact us today to learn how Kistler and ComoNeo can substantially support you with the qualification and validation of your injection molding processes, resulting in zero-defect production, compliance with all standards and regulations, optimized process efficiency, rapid amortization, and data backup and optimization . Choose Injection Depot Group for all your injection molding needs and experience the best service in the market.